Products

Coding of Industrial Products

■ Classification

According to the working pressure and applied water source, reverse osmosis membranes and their components are divided into the following series:

According to the size and application field, reverse osmosis membrane elements are divided into the following types:

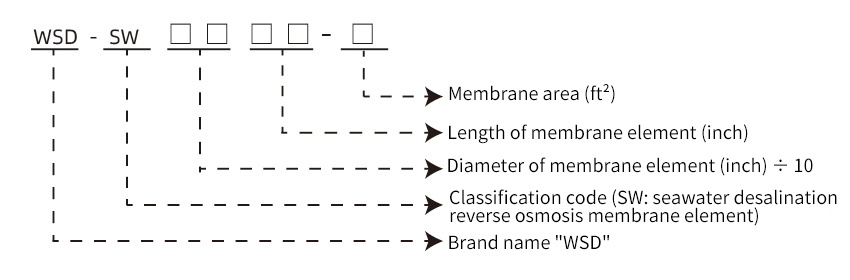

■ Product Naming

The name of the reverse osmosis membrane element consists of the brand name, membrane type and product attributes.

Example: "WSD-5W8040-40O" means a seawater desalination reverse osmosis membrane element with a diameter of 8 inches (201 mm) \ a length of 40 inches (1016 mm) \ a membrane area of 400 ft² (37.2 m²).

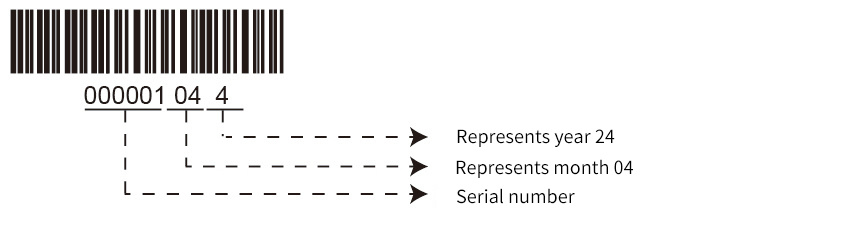

■ Label Barcode

The barcode of the reverse osmosis membrane element is used for the factory to track and trace the production process and quality of the membrane products.

■ Membrane Element Packaging Information

Note: The gross net weight of the membrane element is calculated based on the average value of the dry membrane weight. The error between the actual weight and the average value is ±5%.

■ Frequently Asked Questions

1. How many years can a membrane element generally be used?

The service life of the membrane depends on the chemical stability of the membrane, the physical stability of the element, cleanability, water source, pretreatment, cleaning frequency, operation and management level, etc. Generally, it can be used for 3 years under correct and reasonable operation.

2. How to store the membrane element?

A: The suitable temperature range is 0-45℃; it is recommended to store it at about 25℃ close to room temperature.

B: If conditions permit, it must be avoided from being exposed to temperatures below freezing. If the membrane element accidentally freezes, it must be slowly melted before use, and it will no longer meet the warranty terms after this happens.

C: Even if the membrane element is in the original packaging box, it is not allowed to be exposed to the sun; it is recommended to store it indoors and avoid long-term sunlight exposure.

3. What is the effect of pressure and temperature on water production?

The higher the pressure and temperature, the higher the water production, and vice versa. When operating under higher temperature conditions, the operating pressure should be lowered to keep the water production unchanged, and vice versa. Pay attention to the ability of the membrane component to withstand high pressure and high temperature.

● Product performance may vary under different conditions. The information on this website is for reference only and is not intended to be used as a basis for performance guarantees in actual applications. WSD reserves the right to make changes. If required, clients may consult with our sales representatives about the latest information, of which no further notice will be given.