DTRO membrane process

2024-10-10 17:20

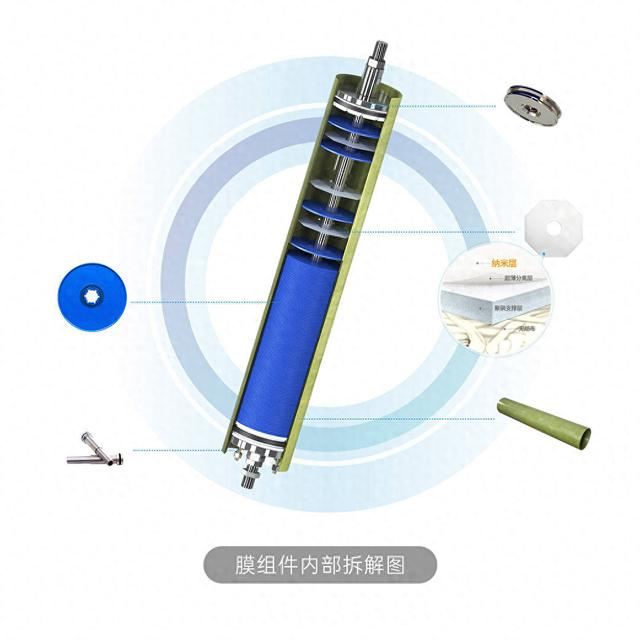

1. DTRO membrane structure

DTRO membrane is a composite membrane, which consists of three layers: support layer, dense layer and contact layer (see the zoomed-in picture below). Among them, the support layer provides the mechanical stability of the membrane, the dense layer controls the water permeability of the membrane, and the contact layer provides the anti-pollution performance of the membrane.

The DTRO membrane column is formed by stacking the reverse osmosis membrane and the guide plate together, fixing them through the central tie rod and the end plate, and then placing them in the pressure-resistant membrane shell. Its main components include: pressure-bearing nut, water production joint, inlet and outlet water joint, upper and lower pressure-bearing flanges, upper and lower water-passing flanges, membrane shell, center rod, guide plate, membrane package, etc. Integration: The pressure

-bearing flange and the water-passing flange are combined into one, taking into account the functions of pressure bearing and flow passing.

Corrosion resistance: The use of duplex steel material improves the overall corrosion resistance and is more convenient for disassembly and assembly.

Strong pressure bearing: The integrated water production sleeve is used as a water production channel component and a pressure-bearing component. It is made of duplex steel and is matched with an integrated water-passing flange.

Internal structure of DTRO membrane module

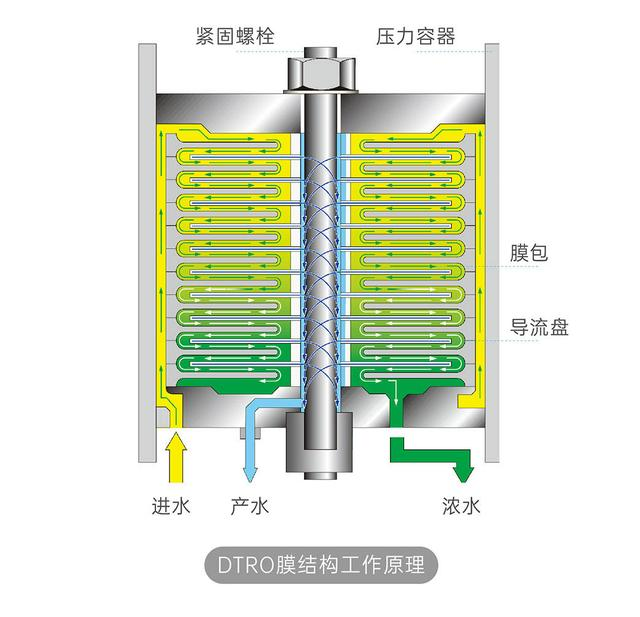

2. Working principle of DTRO membrane

DTRO disc-tube reverse osmosis membrane element assembly adopts the reverse osmosis principle to separate, purify and desalinate molecules in liquid. It can remove various organic or inorganic impurities, including heavy metals, ammonia, various organic substances, inorganic materials and other harmful substances.

DTRO disc-tube reverse osmosis membrane element assembly is mainly composed of disc-type diaphragm (filter diaphragm), guide plate, O-shaped rubber gasket, center tie rod, shell, flanges at both ends, various seals and connecting bolts. Stack the filter diaphragm and guide plate together and fix them with the center tie rod and end flanges. Then put them into the pressure-resistant shell to form a disc-tube membrane assembly. Each component in the membrane column has different functions.

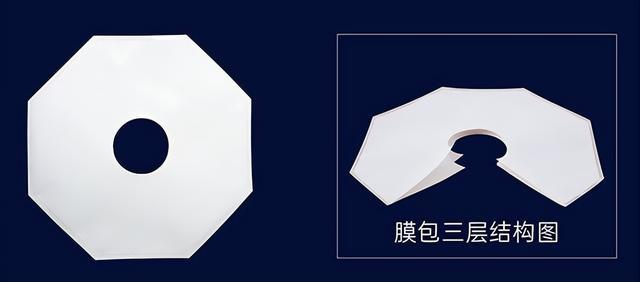

The diaphragm is composed of two concentric ring-shaped reverse osmosis membranes with a layer of filamentary support sandwiched in the middle of the membranes. The outer rings of the three layers of replacement materials are connected, and the inner ring is open to serve as the purified water outlet.

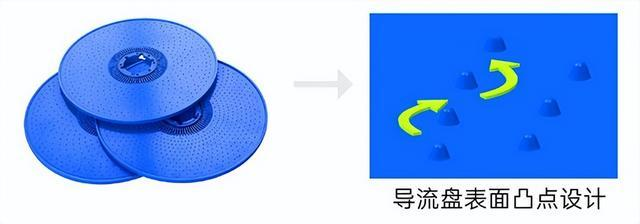

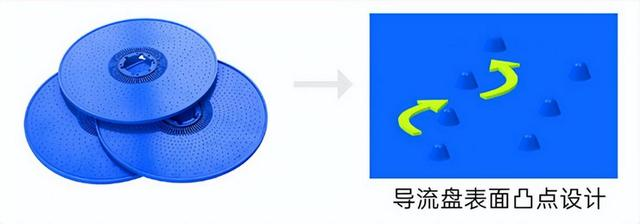

The guide disc (replacing the mesh support layer in the roll membrane) sandwiches the membrane in the middle, but does not directly contact the membrane, widening the fluid channel. The surface of the guide disc has convex points arranged in a certain way, which make the permeate form turbulence under high pressure, increase the permeation rate and self-cleaning function.

The O-shaped rubber gasket is put on the central tie rod and placed in the groove on the side of the guide plate beam to support the diaphragm and isolate the sewage and clean water. The clean water flows in the middle of the diaphragm along the outer periphery of the central tie rod of the filament support flow channel and is discharged through the clean water outlet.

3. DTRO disc-tube reverse osmosis membrane - Features

① Resistance to "four highs":

High pressure resistance: 75~160bar

High SDI resistance: (SDI pollution index) <15

High COD resistance: 1000~20000mg/L

High TDS resistance: 2000~80000mg/L

② Strong anti-fouling:

Convex point wide flow channel: The guide plate adopts unique convex point and turbulence optimization design, and the open flow channel increases the surface flow rate (Reynolds coefficient ≥5000, which is 3-5 times that of the spiral membrane) to avoid solids from being retained on the surface, and has a self-cleaning function. Effectively reduce concentration polarization.

Octagonal structure membrane package:

During high-pressure operation, the patented octagonal structure design causes uneven stress points, which will produce high-frequency vibrations under the impact of water flow, driving the water flow to form an "S" flow and continuous turbulence to avoid pollution and scaling.

③ Low cost:

Standardized and modular configuration, easy to assemble and disassemble.

Easy to clean, good performance parameter recovery.

Simple maintenance, can be replaced and reused separately.

Long service life of membrane components.

④ Strong adaptability:

High-pressure equipment, recovery rate up to 90%.

Stable water quality, single set processing capacity of 5~100m3/h.

IV. DTRO membrane application field

DTRO membrane is a membrane component specially used to treat high-concentration wastewater. It was first used in the treatment of landfill leachate. With its good treatment effect on high turbidity, high SDI value, high salinity, and high COD, and its high pressure and pollution resistance, it can operate effectively and stably even in the case of large fluctuations in water quality and complex components. The application field of DTRO is constantly expanding. The following briefly lists the common DTRO application fields other than landfill leachate:

① Wastewater treatment field:

Desulfurization wastewater represented by coal chemical wastewater and mine wastewater is typically characterized by high turbidity, high salt and high hardness. DTRO disc-tube reverse osmosis membrane can pre-concentrate the mass concentration of desulfurization wastewater TDS from 25~40g/L to 80~100g/L, and the treated wastewater can also achieve near-zero wastewater discharge.

② Water supply desalination field:

Different from the main purpose of wastewater treatment, which is concentration and reuse, desalination in the water supply field is mainly to deal with preliminary desalination under complex raw water conditions. Its common desalination fields include saline-alkali land brackish water desalination, commercial or military seawater desalination and other fields.

③ Zero discharge of wastewater in the industrial field:

Industrial high-salt wastewater represented by chemical park wastewater and electroplating wastewater is essentially similar to ①. The biggest difference is that the DTRO process in the ① field is often in the front stage of the membrane process, while in the zero-discharge membrane process, DTRO mainly treats the concentrated water of the front stage membrane process, that is, it is often in the end stage of the membrane process.

④Other fields:

High concentration acid and alkali or waste liquid recovery; biological protein and collagen recovery; functional sugar concentration, etc. . .

5. DTRO membrane process flow reference

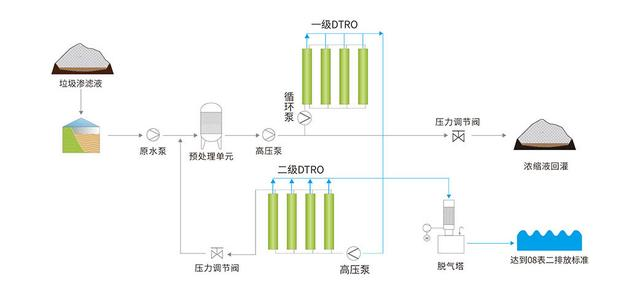

① Leachate two-stage DTRO process flow

The leachate two-stage DTRO process is currently the preferred treatment process for most landfills and incineration plants in the industry. It has stable water quality and can achieve a leachate recovery rate of more than 70%, as follows:

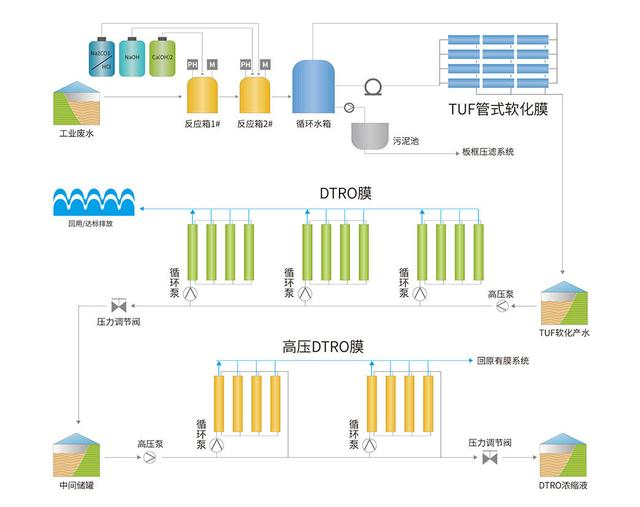

②Leachate 3.0 Process Package

The 3.0 process package of the leachate incineration plant can achieve a recovery rate of more than 85%, as follows:

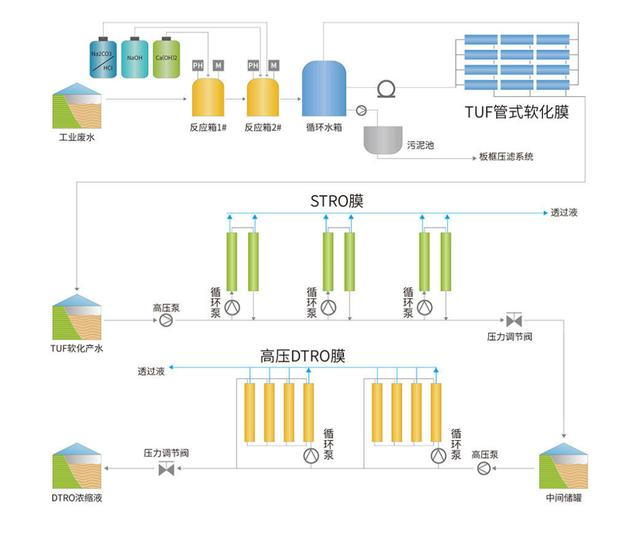

③ Industrial wastewater zero discharge 4.0TSD (TUF+STRO+DTRO) process package

The industrial wastewater zero discharge 4.0 process package can achieve a recovery rate of more than 90%, as follows:

Previous:

Next: