STRO membrane process

2024-10-10 17:13

1. STRO membrane structure

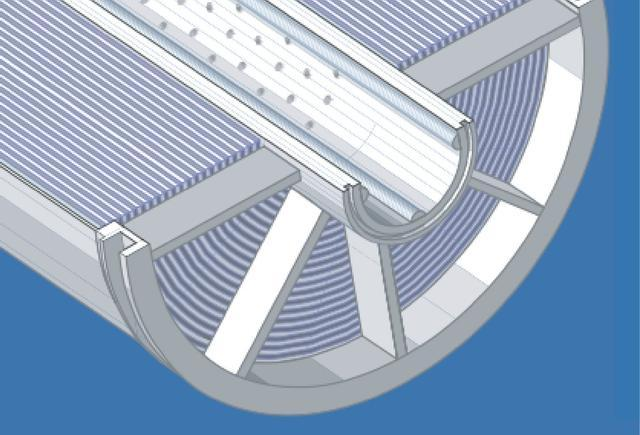

STRO membrane also has a composite structure and is a form of rolled RO membrane, but the design is more complex.

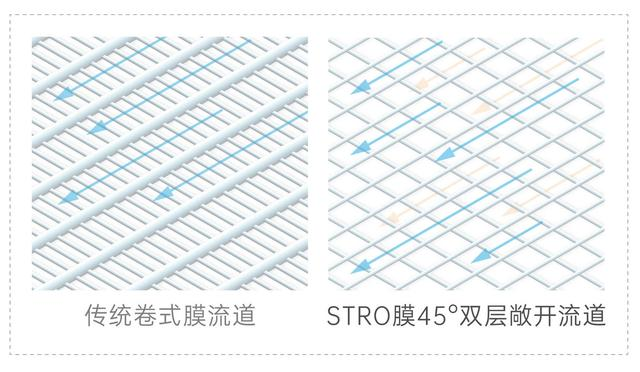

First of all, compared with the traditional rolled RO membrane, there are significant differences in the water supply channel and rolling method as follows:

① Compared with

the traditional rolled membrane, the water supply channel is easy to block and scale, resulting in the inlet water channel. Restricted, the pressure difference increases. The 45° diamond-shaped double-layer open flow channel structure of the STRO pipe network reverse osmosis membrane greatly optimizes the effective area of the inlet water channel and membrane, and the pressure is more stable.

② Compared with the STRO reverse osmosis membrane, the rolling method

shortens the blades and increases the number of blades, shortening the length of the fresh water channel and reducing the pressure loss of the fresh water channel. The net driving pressure along the membrane tends to be the same, and the water flux in different places on the membrane surface can be kept equal as much as possible, thereby reducing the degree of concentration polarization.

Secondly, the STRO membrane is fixed in a fiberglass container with high-pressure end plates and a high-pressure resistant center rod, so that the maximum pressure resistance of STRO can reach 120 bar (different grades of STRO membranes have different pressure resistance levels).

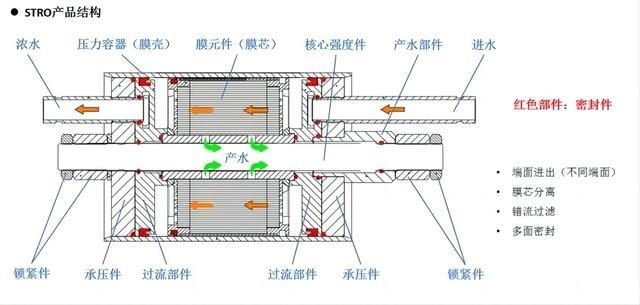

2. Working Principle of STRO Membrane

The membrane of STRO module adopts industrial anti-pollution reverse osmosis membrane, and the grid channel adopts a parallel grid structure that is different from the general roll membrane. The grid of STRO module adopts a trapezoidal structure. The wastewater/liquid flows in the channel formed by the grid, just like flowing in a tubular membrane, and the resistance is much smaller than that of the diamond grid; at the same time, the internal transverse reinforcement ribs can increase the turbulence of the liquid flow, reduce the concentration polarization effect of the membrane, and improve the pollution resistance of the STRO module. Its basic product structure and structural working principle are as follows:

3. STRO pipe network reverse osmosis membrane - characteristics

① High desalination rate:

The desalination rate reaches 99% under standard test conditions, and the performance is stable, the product water quality is better, and higher water use indicators are achieved.

② Anti-fouling and clogging:

The special fluid hydraulic design reduces concentration polarization and improves the tendency of fouling and scaling.

③ Special flow channel:

The 45° diamond double-layer flow channel design is adopted, which has better cleaning effect and easier performance recovery.

④ Easy maintenance:

The modular design of 1-6 units that can be assembled in series is adopted, which is easy to clean and maintain.

⑤ Small footprint:

The membrane has a high stacking density, the equipment occupies a smaller area, and the project cost is reduced.

⑥ Low cost:

The number of seals is small, maintenance is easier, the service life is increased, and the replacement cost is greatly reduced.

IV. Application fields of STRO membrane

① Wastewater treatment field

In terms of wastewater treatment, STRO membrane can effectively remove harmful substances and suspended solids in wastewater, so as to improve water quality.

② Food solid-liquid separation field

In the food industry, STRO membrane is particularly suitable for treating liquids with high viscosity, easy scaling or high suspended solids content, such as milk, juice and other food industries due to its anti-pollution performance and washability.

③ Biomedicine field

In biomedicine, STRO membrane is used to separate and purify biological molecules, prepare drugs, etc.

In addition to the above fields, STRO membrane also has good applications in circulating cooling water, landfill leachate, mine wastewater, chemical wastewater, coal chemical wastewater, coking wastewater, electroplating wastewater, steel wastewater, etc.

Although DTRO and STRO have very different structures and different functional focuses, based on the fact that both have good salt and COD resistance, in practical applications, we often see that the two will complement each other and play their respective advantages. For example, in some cases, DTRO membrane can be used for preliminary liquid purification, and then STRO membrane can be used for fine liquid separation. In this way, the high flux performance of the DTRO membrane can be fully utilized, and the excellent anti-fouling performance of the STRO membrane can be utilized to achieve better separation effects.